Grouting: It is defined as the process in which the movable materials( also called Grout ) is injected into soil or rock to achieve a desired composition for a particular purpose like

- for making soil enough strong to bear the load will exert on it.

- for waterproofing the soil or structure.

- to fill the cracks and pores in rock or in any structure.

Basically the grouting process involve the process in which we drill a bore hole or driven a pipe through which we fill the grout at a particular pressure. The depth of bore hole and spacing between the hole depends upon following

- Load that will applied on soil or structure

- Presence and nature of voids present in soil or rock

We can classify the grouting process into following part on basis of grout material used

- Cement grouting: Cementitious grout has higher permeability. The composition of cement and water varies according to conditions but some mixture of sand and cement(4:1) is used as grout. Some time secondary holes are made near primary hole to ensure complete grouting.

- Bituminous grouting: Basically Bitumen emulsion can serve as a suitable grouting material that can be injected into sands and act as a waterproofing material. It is basically used at dams and other water bound structure.

- Chemical grouting:Chemical grouting is used in soils of medium to coarse grading. Chemical such as sodium silicate and calcium chloride are mixed together in liquid form and solidified into a gel. The chemicals are either mixed together before injection or mixed after injection.Chemical grouting allows economical spacing of bore holes and more flexibility.

- Resin grouting: Resin grout has low viscosity which allow grout t penetrate in fine sand easily. The presence of chemical in water present at site decide the resin type. The common used resin are:

- tannin-based grouts.

- Phenol-formaldehyde

- Resorcinolformaldehyde

Basically grouting is a soil improvement technique used to make soil enough strong to bear the various stress applied on it.

We can divide the grouting on the basis of method of operations:

1.Permeation Grouting: The grouting in which joints,cracks and pores are filled with grout without disturbing the formation of soil structure to form a solidify ground to increase the bear load. It is low pressure injection system. Cement and chemical based grout is used in these method. We can use the method as depth maximum up to 60 m. These method is used in dam engineering or waterproofing the structure by creating a wall type structure in soil.

Advantages of Permeation Grouting:

- Clean and Undisturbed soil structure

- Zero environment impact

- Time efficient

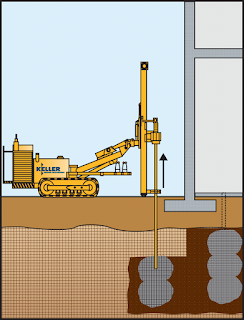

2.Compaction Grouting: The grouting in which the soil is displaced when grout is filled in the ground. It is used where foundations of existing structure needs improvement as these process enables us to fill grout at an inclined angle. These method is used to re-leveling the base, to stop liquefaction of soil etc.

In these process, a thick and less mobility grout is used because on expanding of grout, it displace the soil and densify it. On injection of grout, the bulb shaped structure is formed.

3.Hydro Fracture Grouting (Compensation Grouting) : The grouting in which the fracture are deliberated by using grout under high pressure. A highly mobile slurry of cement, sand and water is used to fill the fracture under pressure at predefined place. When the pressure exceed, the fracture open up and the empty space is filled by grout quickly. In result, the soil thicken and increase in length.It formed root like structure or thin lens shaped. It is used for wide range of soils like gravel, loose soil or even for clay etc.

4.Jet Grouting: The grouting technique in which the grout is injected at high pressure and high velocity which erode and excavate compacted the soil. It is fruther divide into 3 categories: Single fluid (cement grout), Double fluid (Cement grout and air) and triple ( Cement grout, air and water).

In these method, drill stem is rotated and material is sprayed with special nozzles. The size of coloumns depends upon the type, structure of soils, presence of voids, pressure and velocity intensity of grout.

It is used in:

3.Hydro Fracture Grouting (Compensation Grouting) : The grouting in which the fracture are deliberated by using grout under high pressure. A highly mobile slurry of cement, sand and water is used to fill the fracture under pressure at predefined place. When the pressure exceed, the fracture open up and the empty space is filled by grout quickly. In result, the soil thicken and increase in length.It formed root like structure or thin lens shaped. It is used for wide range of soils like gravel, loose soil or even for clay etc.

4.Jet Grouting: The grouting technique in which the grout is injected at high pressure and high velocity which erode and excavate compacted the soil. It is fruther divide into 3 categories: Single fluid (cement grout), Double fluid (Cement grout and air) and triple ( Cement grout, air and water).

It is used in:

- Construction of horizontal barriers

- Control of ground water

- Underpinning

- Tunnelling

- Support to excavation

5.Deep Mixing Method: The technique involves deep layer mixing treatment in which cement slurry is injected and mixed to solidify the ground. In these method, a hole is drilled by a drilling shaft and slurry is injected. While drilling shaft coming out of hole, mixing is continuous.

The method fruther divided into 2 categories: dry process and wet process. The depth of coloum for dry process is 60 ft and for wet process is 100ft

The method fruther divided into 2 categories: dry process and wet process. The depth of coloum for dry process is 60 ft and for wet process is 100ft

0 Comments